Posted On: 27 DEC 2023 3:40PM by PIB Delhi

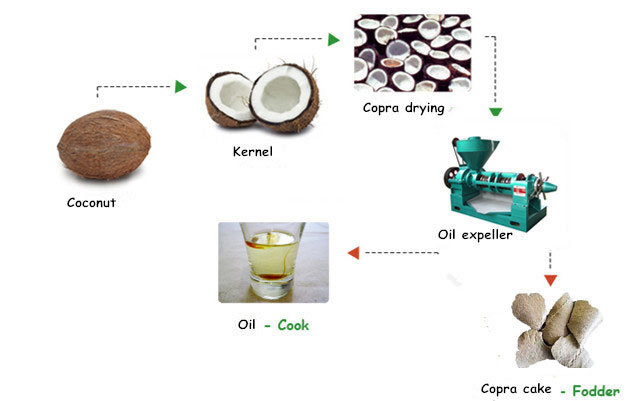

The Cabinet Committee on Economic Affairs chaired by the Prime Minister Shri Narendra Modi, has given its approval for the Minimum Support Prices (MSPs) for copra for 2024 season. In order to provide remunerative prices to the cultivators, government had announced in the Union Budget of 2018-19, that MSPs of all the mandated crops will be fixed at a level of at least 1.5 times of all India weighted cost of production. The MSP for Fair Average Quality of milling copra has been fixed at Rs.11,160/- per quintal and for ball copra at Rs.12,000/- per quintal for 2024 season. This will ensure a margin of 51.84 percent for milling copra and 63.26 percent for ball copra, which are well beyond 1.5 times the all India weighted average cost of production. Milling copra is used to extract oil, while ball/edible copra is consumed as a dry fruit and used for religious purposes. Kerala and Tamil Nadu are major producers of million copra, whereas ball copra is produced predominantly in Karnataka.

The MSP for 2024 season is an increase of Rs.300/- per quintal for milling copra and Rs.250/- per quintal for ball copra over the previous season. In the last 10 years, the Government has increased MSP for milling copra and ball copra from Rs.5,250 per quintal and Rs.5,500 per quintal in 2014-15 to Rs.11,160 per quintal and Rs.12,000 per quintal in 2024-25, registering a growth of 113 percent and 118 percent, respectively

A higher MSP will not only ensure better remunerative returns to the coconut growers but also incentivize farmers to expand copra production to meet the growing demand for coconut products both domestically and internationally. In the current season 2023, the Government has procured a record amount of more than 1.33 lakh metric tonnes of copra, at the cost of Rs.1,493 crores, benefiting around 90,000 farmers. The procurement in the current season 2023 indicates a rise of 227 percent over the previous season (2022).

National Agricultural Cooperative Marketing Federation of India Ltd. (NAFED) and National Cooperative Consumers’ Federation (NCCF) will continue to act as Central Nodal Agencies (CNAs) for procurement of copra and de-husked coconut under Price Support Scheme (PSS).